1. Real-Time Monitoring and Rapid Response

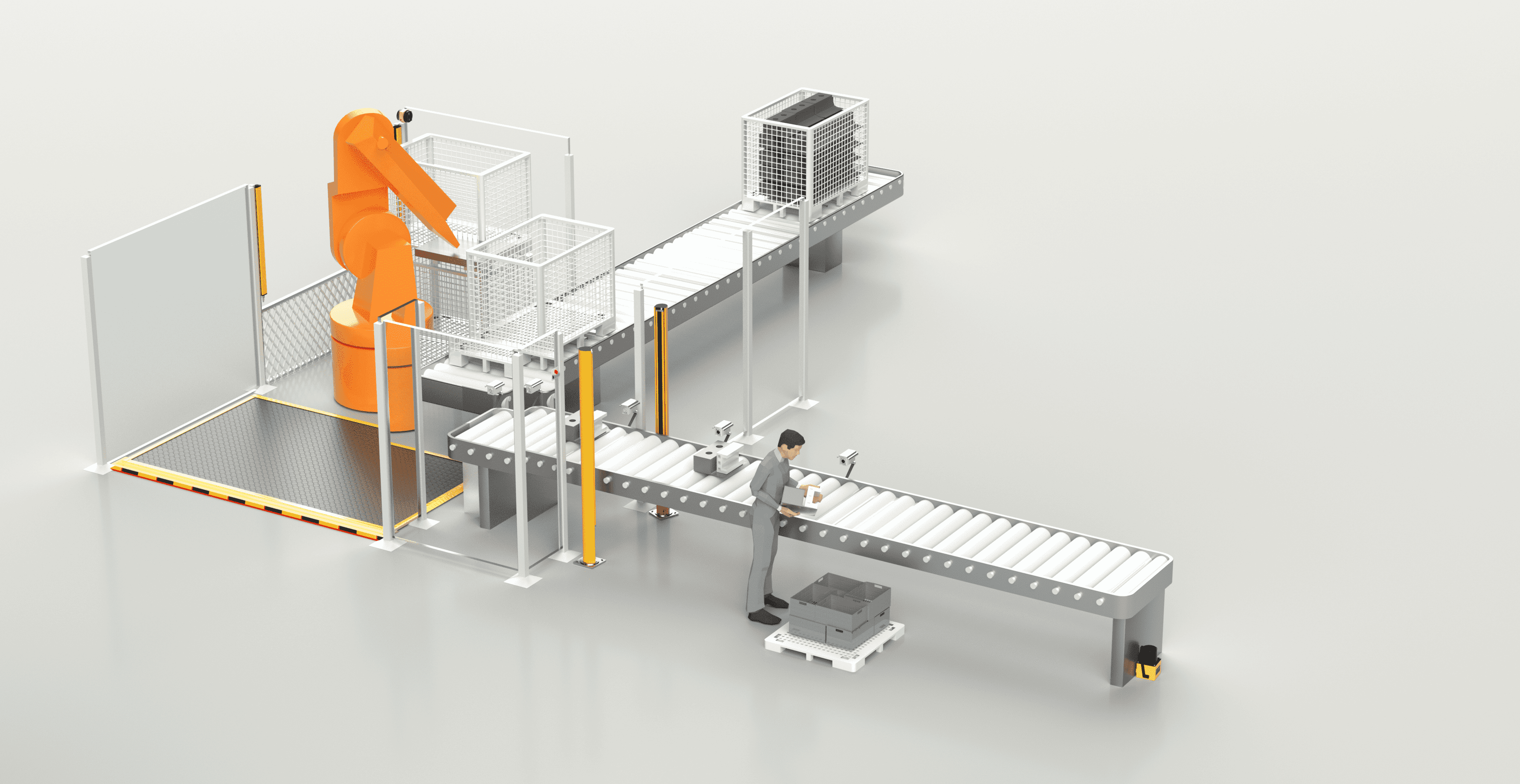

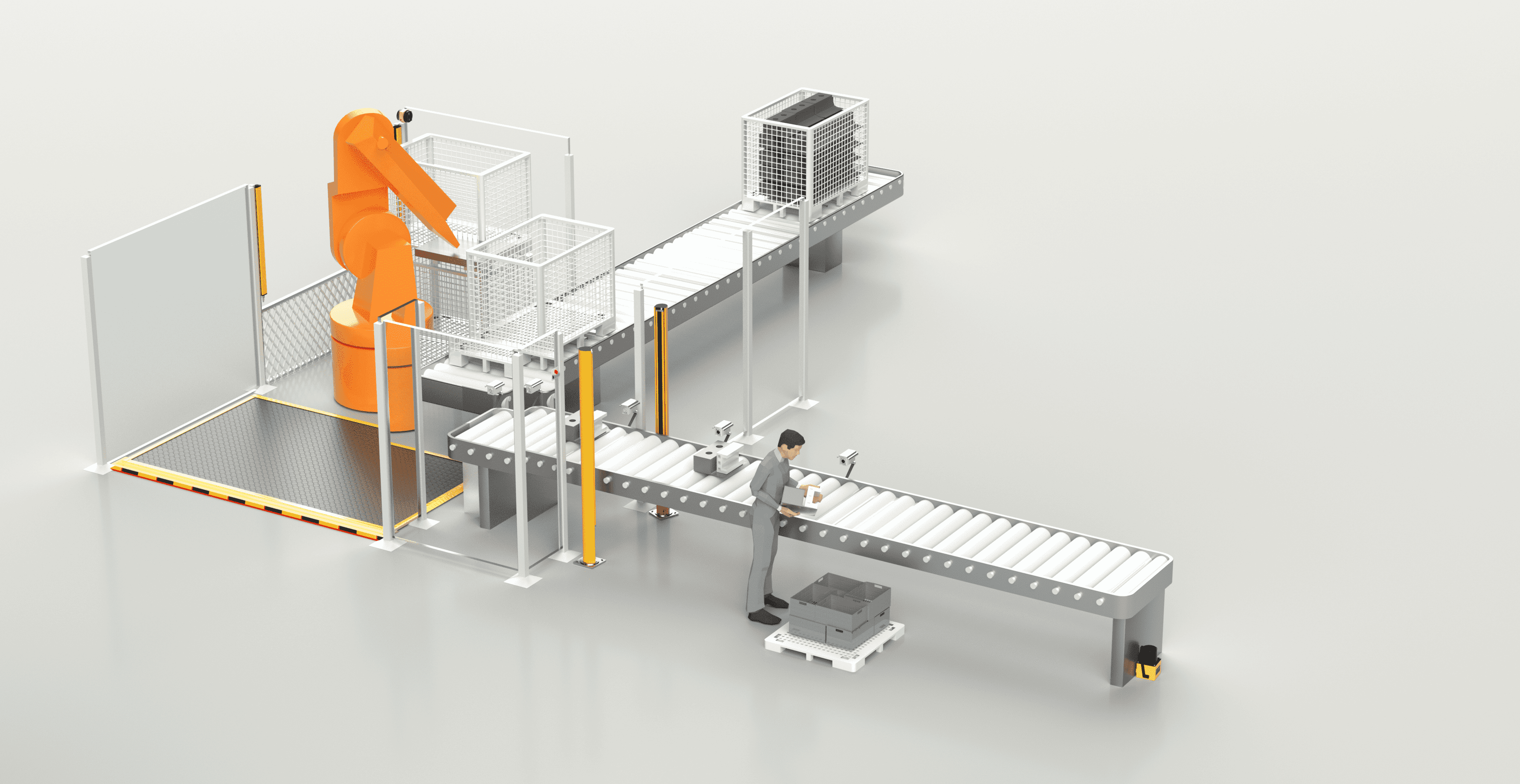

Safety pressure-sensitive mats feature highly sensitive pressure sensors that can instantly detect weight changes (such as a worker stepping into the robot's work area) and trigger the machine's stop function. This instant response effectively prevents potential accidents.

2. Flexible Configuration and Easy Installation

Safety mats are relatively easy to install and can be flexibly configured to cover different areas of the robot's workspace. Their modular design allows for easy expansion and maintenance, making them highly adaptable. Safety mats can be customized in different sizes and shapes to meet specific user requirements. They can be easily installed in various locations and connected in series or parallel to form larger protective areas as needed

3. Enhanced Safety with Reduced Downtime

Compared to traditional fencing or light curtains, safety pressure mat sensor ensure safety without significantly impacting production efficiency. When pressure is detected, the system automatically halts operation and can quickly resume production once the hazard is resolved, reducing downtime due to safety concerns.

4. Wide Range of Applications

Safety mats are suitable for various industrial environments. They are commonly used in automated production lines, such as automotive manufacturing, electronics production, and welding robot workstations. They are also used in hazardous areas like chemical processing and pharmaceutical manufacturing, where they help prevent accidents by detecting the presence of personnel or objects.

5. Strong Chemical Resistance

The protective layer of the safety mat has excellent chemical barrier properties. It is resistant to various chemicals such as diluted acids, diluted alkalis, non-oxidizing acids, metalworking oils, vegetable oils, alcohols, and soapy water. This makes them suitable for use in harsh chemical environments.

6. User-Friendly and Efficient

Compared to other protective methods like mechanical barriers, sliding doors, and pull-back limiters, safety mats are more flexible and labor-saving. They allow for full visibility and access to the work area while enhancing safety. They also simplify routine tasks such as machine setup, maintenance, and repair